Extraction of dust from manufacturing processes

Systems for filtration of smoke, dust, and particles

In many heavy industry factories, a variety of manufacturing processes are carried out:

- Welding and soldering

- Machining such as cutting, drilling, turning, polishing, and sharpening of steel/aluminum, complex materials, and more

- Spreading of volatile materials and adhesion

- Sawing, sharpening, and filing of wood, carton, plastic, rubber, and more

- Transport, mixing, or packaging of powdered materials in the food, pharmaceutics, chemistry industry, and more

After learning about the problem, examining all repercussions on the factory work environment and its surroundings, and examining the type of pollutant and the authorities’ requirements, AMS designs and plans the solution while considering the number of workstations and their locations in the factory.

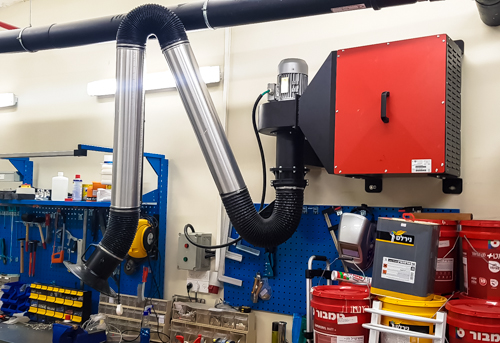

As part of the solution, we provide systems that include, in addition to the extraction means at each station and/or machine, the extraction and filtration facility suitable to the type of pollutant, the number of extraction stations, and the requirements of the plant and the authorities.

Many extraction facilities include automatic compressed air cleaning systems, which have important advantages, such as:

- High filtration efficiency of the filters over time

- Long term preservation of the filter life

- Convenient operation and maintenance of the facilities

- Easy and safe removal of pollutants collected by the facilities, to a waste treatment site or recycling

The filtration facilities and extraction fans are normally installed outside the building, to save precious space on the manufacturing floor, and to remove the noise centers from the workers, for a safer and more pleasant work environment.

Many factories have air conditioned work areas. Extraction and removal of the air from the building will cause loss of treated air, and compromise the micro-climate conditions. For this purpose, filtration facilities with integral extraction fans have been developed and installed inside cells with acoustic insulation.

Thus, a safe and convenient work environment is maintained for the benefit of the workers, without noise hazards.

The facilities are placed in the plant, the clean air is emitted back into the area, and all without harming the microclimate conditions.

In systems where the fans are adjacent to the filtration facility and not inside it, silencers are installed to minimize the noise hazard.

The system is adjusted to include filters suitable to the different types of pollutants such as dust, smoke, particles, fumes, etc.

The air filtration capacity of such systems reaches 99.97%.

Proper planning of the systems enables local extraction of the pollutants with means such as articulated extraction arms or cross flow fume cupboards, dust collectors, downdraft tables, etc.

We invite you to contact us, and make an appointment with us in the field

The technical, engineering and managerial experience accumulated in the company enables the provision of solutions using the latest methods available on the market and together with rich experience in project management, AMS brings the customer the best solution, in the required time and uncompromising quality.