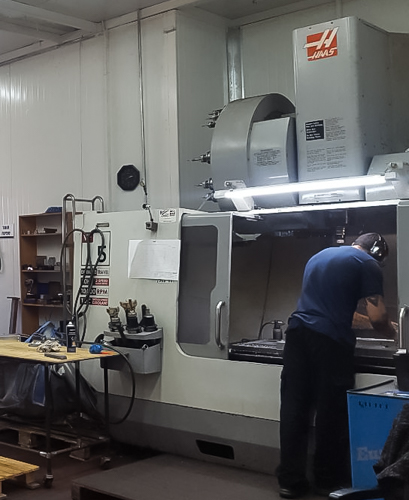

Filtration of oil vapor and emulsion from machining processes

Projects purpose:

Filtration of oil vapor and emulsion from machining processes

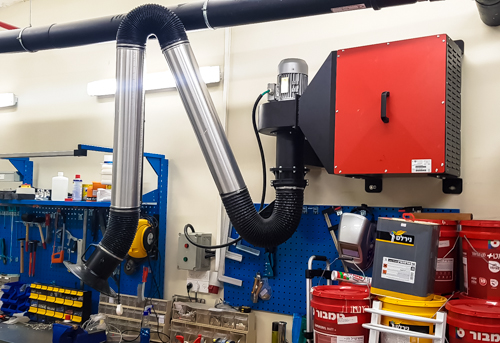

Solution:

Supply and installation of hcy model filtration systems.

For coolant extraction for sliver processing.

The systems are designed for an air flow of 2000 kWh each.

The systems include a highly efficient initial mechanical separator which drains most of the oil back into the machine or collection tank.

This configuration reduces the load on the final filter and reduces the frequency of filter replacement – up to 10,000 working hours between replacements.

For 99% filtration capacity systems and the filtered air is returned to the building space.

The system includes as standard a final filter of the activated carbon type for reducing residual odors.