Downdraft tables for sharpening and polishing

Downdraft tables

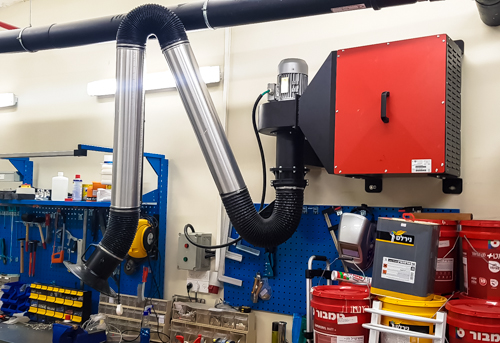

AMS specializes in technological ventilation solutions for maintaining the quality of the work environment and keeping the workers safe. Our leading solutions include downdraft tables that serve as worktables.

This technology has been developed by us over the years for extraction of dust and particles emitted to the work table during chafing, polishing, sharpening, and drilling of metals, wood, plastic, and rubber, as well as fumes, gasses and odors emitted during application of paint, lacquer and glue, treatment of powdered material, weighing, packaging, etc., and their removal to a treatment and filtration facility. These systems maintain the principle of ventilation based on air exchange in the volume of the building.

Systems with downdraft tables can be found in different types of industries: welding workshops, carpentry shops, garages, metal factories, security industries, and many more.

Ventilation and extraction systems with downdraft tables are intended for various types of use, such as extraction of gasses, odors, toxic fumes, electronic soldering smoke, welding smoke, powders and particles emitted during various processes, and more.

There is a large variety of standard tables in various dimensions. in addition, AMS manufactures tables at the client’s demand or according to the work nature and dimensions of processed products.

In basic tables, extraction is carried out on the horizontal work surface. In other tables, in addition to extraction on the horizontal surface, there is a double back wall, a fume cupboard, through which extraction is carried out during work.

To enable a large variety of uses, we have planned and developed tables with solid extraction systems, tables with external or internal centrifugal fans, and tables that come with filtering and/or active coal devices for absorbing odors and gasses.

For tables with fans installed internally, an emphasis was put on internal acoustic insulation for maintaining a low noise level and preventing a noise hazard to the workers.

The dust and particles are sucked from the work surface and the font fume cupboard (if any), and the particles sink to the lower part of the table, where they are collected into waste drawers for extraction and cleaning.

The table’s internal structure is planned to provide an internal separation of the raw particles, and the milder dust passes to the filtration facility, where it is treated.

in systems with external filtration and collection facilities, such facilities include integral mechanisms for cleaning the filters.

The tables are selected or planned to adapt to the nature of their use, the size of the particles and the types of dust emitted during work.