Oil fumes filtration and emulsion for sliver processing

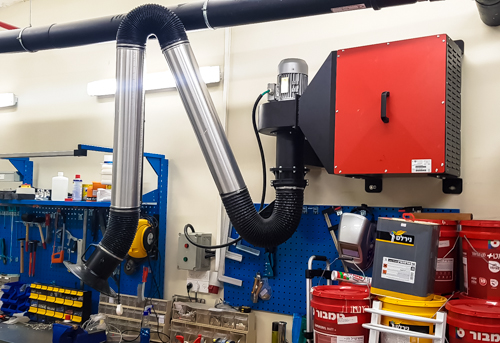

Systems for extraction and filtration of cooling liquid fumes

In many factories in the metal industry, smart machines are used for enclosed or open workspaces.

These machines carry out manufacturing processes such as cutting, drilling, turning, polishing, and sharpening of steel, aluminum, complex materials, and more.

During these processes, cooling liquids such as cooling oil or emulsions are used, and as a result of them being sprayed or heated, fumes, smoke, and odors are emitted to the building space, causing pollution, and harming the work environment and possibly the workers’ health.

After thorough examination of the problem, AMS provides solutions that take into account all of the site data, such as: effects on the work environment and its surroundings, types and number of machines at the site, cooling liquids used at the site, number of machines in which pollution treatment is required, location of the extraction and filtration facility, extraction means and their connection to the machines, and placement of the system’s transport pipes in the building, in order to prevent disruption of the manufacturing processes in the factory.

These extraction and filtration facilities enable the return of most filtration liquids that are collected in them back to the manufacturing processes, thus sparing the purchase costs of new liquids.

The main advantage of the filtration facilities are:

- Maintenance of workers’ health and provision of a safe and convenient work environment

- Convenient operation and facility maintenance

- Easy and safe collection of liquids by the facilities, possibility for their recycling

The filtration facilities and the extraction fans are normally installed inside the building. Many factories have air conditioned work areas, and extraction and expulsion of air from the building may lead to loss of conditioned air and harm to the micro-climate conditions. For this purpose, we have developed filtration facilities with integral extraction fans installed in cells with acoustic insulation. Thus, a convenient and safe work environment, clear of noise hazards, is maintained for the benefit of the workers.

The filtered air is emitted back into the building without harming the microclimate conditions.

In systems where the fans are installed adjacent to the filtration facility and not inside it, silencers are installed to mitigate noise hazards. The air filtration capacity of such systems reaches 99.97%.

In systems with several extraction locations (machines), we will use a transport pipe system comprised of sections connected by banderoles and sealants.

This method enables clearance and cleaning of liquid accumulation and small particles that may pass through the pipe system.

We invite you to contact us, and make an appointment with us in the field

The company’s technical, engineering and managerial experience enables the provision of solutions using the latest methods available on the market and together with rich experience in project management, AMS brings the customer the best solution, in the required time and uncompromising quality.