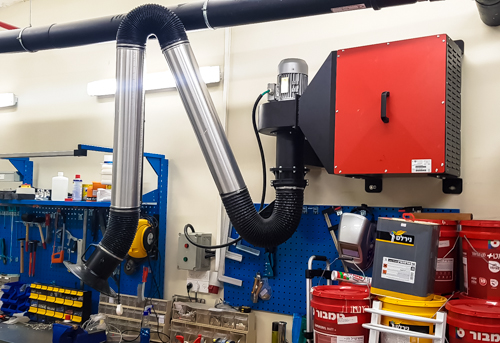

Installation of blowers for central Extraction systems

Projects purpose:

Extraction air saturated heat oil and smoke from 8 industrial kitchens in parallel

Solution:

Our company designed and supplied blowers from the bcs series

Model bcs-710-R

Power -15 kw

25,000 kWh per unit

100mm water resistance

The blowers were inspected and approved by the Israeli Standards Institute and approved for smoke evacuation in an emergency Standard 1001 Part 7.

These blowers are designed for continuous work in harsh working conditions

The blowers are supplied as standard with an access opening for testing and cleaning the blower accelerator, and with an opening for draining liquids.

These blowers are designed to work in oil-saturated air and the smoke of the accelerator paws straight back so that its self-cleaning capability is excellent, no material can stick to it and there is no fear that it is out of balance.

The bcs series blowers feature many manufacturing technologies that reduce the noise level and improve the efficiency exceptionally.

The suction cone structure is very deep which significantly improves the electric efficiency of the blower.

The accelerator parts are connected by continuous welding in order to withstand high working loads.

A long, detachable suction neck makes it very easy to connect the system to the suction ducts.

The blower can be disassembled into 3 parts very quickly, for installation in places where it is not possible to transport it by crane.

This series of blowers with a diameter of 250 mm to a diameter of 1000 mm are on the shelf and delivered within 24 hours from the moment of order

We invite you to contact us, and make an appointment with us in the field

The company’s technical, engineering and managerial experience enables the provision of solutions using the latest methods available on the market and together with rich experience in project management, AMS brings the customer the best solution, in the required time and uncompromising quality.