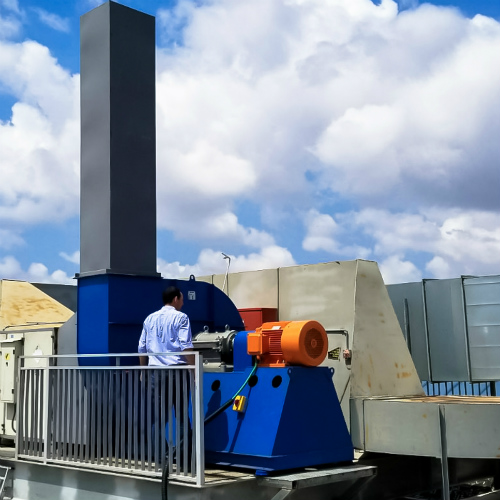

Manufacture and installation of central suction blower

Projects purpose:

Design, production and installation of a central suction blower for a flow of 36,000 kWh against a vacuum of 180 mm.

Solution:

Our company designed and chose to supply industrial kb series blower:

Model kb1200 ar8.

Accelerator diameter 1200 mm.

Spoon accelerator straight back.

Blower arrangement 8- The accelerator is connected to the motor shaft via a flexible elastic connector [clutch].

30kw motor power.

Working speed rpm 900.

For a closed ball bearing that contains about 8 liters of oil, the oil change is required once every few years and beyond that no maintenance operations are required.

The working speed of the blower is extremely low and the noise level is very low.

The blower has a heavy industrial structure, and includes as standard a service opening in the coop for testing and handling the blower accelerator

All blower parts are connected in continuous welding by a robot.

The accelerator paws are connected in continuous welding to the accelerator body as standard. This connection configuration allows it to withstand particularly large working loads without fear of mechanical failure.

The suction cone is manufactured by giant presses and with the help of this mechanization the cone can be deepened to the accelerator depth which significantly improves the efficiency of the blower.

The blower was designed and manufactured in a very short time and at a competitive price to the satisfaction of the customer

We invite you to contact us, and make an appointment with us in the field

The company’s technical, engineering and managerial experience enables the provision of solutions using the latest methods available on the market and together with rich experience in project management, AMS brings the customer the best solution, in the required time and uncompromising quality.