Downdraft tables for polishing metal products

Projects purpose:

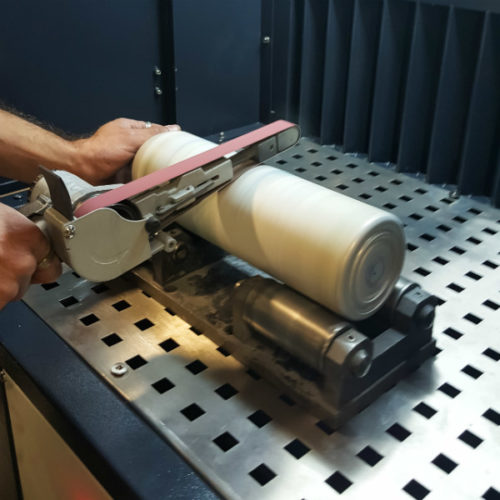

Extraction of aluminum particles from the process of polishing pressure vessels

Solution:

1 meter long tgt polishing and grinding downdraft table.

The pumping is done from a perforated work surface and a perforated back wall,

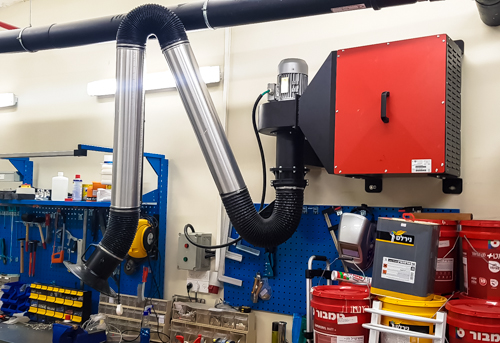

The air flow is very high, about 3,600 kWh in favor of efficient capture of particles that fly with great force from the pneumatic polishing system.

The system is equipped with filters with a filtering capacity of 99.95%.

The filtered air is returned back to the room space and there is no loss of air-conditioned air.

For maintaining a high suction power, the system is equipped with an automatic filter cleaning mechanism that includes a spiral nozzle for efficient and quiet cleaning of the filters.

The sides of the table open to insert large parts.

The downdraft table also includes a toolbox with a built-in electrical outlet and top lighting.

The suction blower is installed in an acoustic chamber.