Production and installation planning of a cyclone for shell separation

Projects purpose:

Separation of peanut husks from production line and packaging

Solution:

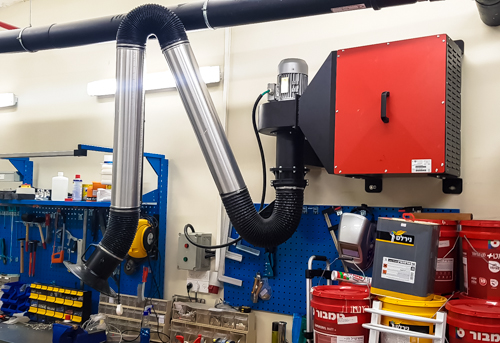

Our company has designed and installed an efficient and simple shell separation system.

Suction head made of PLBM 304, 40 cm wide, suction head above and placed on a conveyor belt.

Cyclone separator model max flow,

This model is very efficient and includes simple and smart technological advantages.

The suction blower is placed at the top of the cyclone in this configuration. Large particles are prevented from reaching the accelerator and the coil so that the blower does not wear out.

In addition, in this configuration the noise level remains extremely low and the cyclone can be placed near the production line and the production personnel without producing a noise hazard.

The separator includes a final bag-type filtration system. This system filters the small dust particles with very high efficiency, so that the air that is returned to the room space is free of particles and creates a safe and comfortable working environment.